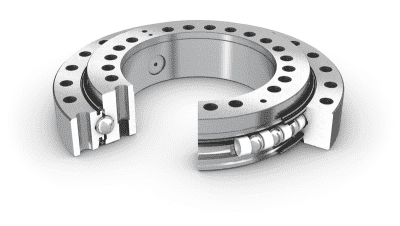

Hauv CNC ntsug tshuab dhos tshuab, tusCov Kab Mob Slewingyog ib qho ntawm cov tseem ceeb ntawm cov khoom siv uas cuam tshuam lub tshuab tag nrho thiab paub cov machining qhov tseeb ntawm lub workpiece. Peb xav kom nws khiav ntawm kev kub ceev thiab tiv taus hnyav workpieces nyob rau tib lub sij hawm, nrog precise khiav qhov raug thiab anti-tiltingLub peev xwm Torilate Torque, thiab tus Cov Kab Mob Slewing yog tus yuam sij kom ua tiav lub rooj txhawb nqa.Qhov kev teeb tsa kev hloov kho ntawm lubpuvnqhisyam khoom uas pabKuj yog qhov nyuaj, cov kev sib ncag yog qhov nyuaj dua los xyuas kom meej, tag nrho qhov tseeb ntawm lub rooj yog qhov nyuaj los txhim kho.

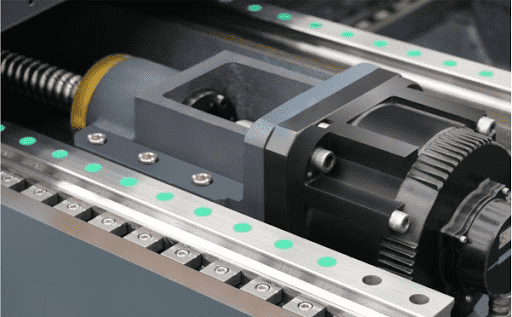

Raws li qhov tshwm sim, kev cog lus ntau duaHla Cov Menyuamnqhispom kevtau siv uas muab cov khoom siv txuag nyiaj, qhov yooj yim tsim kev daws teeb meem, txhim kho cov nrawm dua, txhim kho cov khoom raug thiab ruaj khov, thiab siab duaThauj khoom muaj peev xwmthiab rigidity. Kab lus no piav qhiaapplricationraunqhisyam khoom uas pabHauv CNC Ntsug Tshuab Dhos kom ua tiav lawv cov khoom siv zoo tshaj plaws.

1.run-tawm qhov tseeb

Nqhis dej bPob ntseg khiav-tawmtuaj yeem muab faib ua cov khoom siv sib xyaw thiab cov kab mob uas muaj kev sib tsoo ntawm cov rooj sib tsoo .Yog li ntawd, kev tswj tau zoo dua qub ntawm lubnqhisyam khoom uas pab asynchronous khiav-tawm, tus me dua zaum kawgradial thiab axial khiav-tawmntawm cov haujlwm ua haujlwm thiab qhov siab dua qhov raug ua haujlwm. Hauv kev xaiv ntawmnqhisyam khoom uas pab hom thiab qib siab, nws pom zoo tsis yog tsom rau xwb nqhisCov kabmob sib dhos khiav-tawm, tab sis yuav tsum muaj kev nkag siab tob ntawm qhov cuam tshuam ntawmnqhisyam khoom uas pabasynchronous run-tawm cov qauv precision.

2.shape thiab chaw nyob

Tus Cov Kab Mob Slewingtus pas Mounting qhov chawthiabIav nplhaibxav kom tiaj tiaj, kev sib tw, kev sib tw thiab hliav cij uas tau ua raws likev nplignqhispom kevCov. Kev tswj hwm cov ntawv no thiab txoj haujlwm thev tsis tau tsuas yog ua kom sib txawv zoo dua, tab sis kuj tseem ua kom muaj kev ntxhov siab ntau dhau los ntawm eccentricity ntawmtusLub Suab RearingSab hauv thiab sab nraud ntiv nplhaibthiab ntevQhov kev pabcuam lub neej ntawm covnqhisyam khoom uas pabCov. Hais txog kev ua qauv ntawm daim ntawv thiab Lub Suab RearingTso kev tiv thaiv, nws raug nquahu kom tham peb ncaj qha kom phim lawv nqhisCov kabmob raug.

3. Axial Preload

Kev txiav xeem ntawm CNC ntsug lathes them ntau saib rau qhov roughness lub ntsej muag thiab ib qho ntawm lub voj voog, thiab ib qho ntawm cov yuam sij ntawm lub voj voog los txiav txim siab nws qhov kev ua tau zoo yog qhov tsis sib xws ntawm cov kab ke. Qhov nruj ntawm cov kab ke suav nrog cov qauv sib dhos ntawm cov qauv qauv, qhov tsis sib haum ntawm cov nqhisyam khoom uas pab, etc. lub rigidity ntawm lub nqhisyam khoom uas pabfeem ntau nyob ntawmCov Kab Mob SlewingAxial Preloing.

Yog li ntawd, nws yog ib qho tseem ceeb heev los xav txog qhov cuam tshuam ntawm kub thiab thauj khoom, thiab teeb tsaAxial Preload ntawm lubnqhisyam khoom uas pab.

Lub sij hawm Post: Aug-31-2020