Xuzhou Wanda Searing Cov Kabmobyog cov chaw tsim khoom tshwj xeeb hauvCov Kab Mob Slewingthiabtus ntxiasCov. Niaj hnub no, cov chaw tsim khoom yuav qhia rau koj tias yog dab tsi tshwm sim hauv qab.

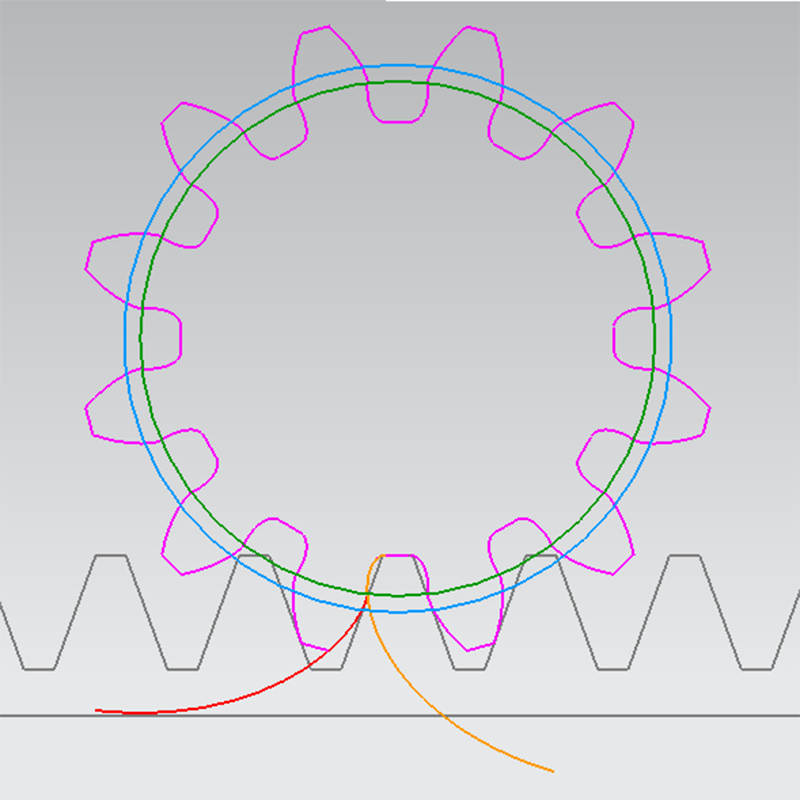

Nyob rau hauv cov txheej txheem ntawm machining intolute iav nrog cov qauv tsim tawm, qee zaum tus hniav sab saum toj ntawm tus hniav ntawm lub hauv paus ntawm lub iav ntawm lub iav kom tau machined. Qhov tshwm sim no hu ua kev sib koom ua ke.

Undercutting tshwm sim vim tias cov hniav sab saum toj (khib hom cuab yeej) lossis cov hniav sab saum toj (iav cutter). Yog tias kev ua raws li tshwm sim thaum lub ntsej muag slewing iav thiab pinion mesh, nws yuav tsis muaj zog rau cov kis tau tus mob, thiab tseem yuav tsum tau zam kom deb li sai tau.

Cov nyhuv: tom qab undercutting, qhov tuab ntawm slewing bearing hniav hauv paus yuav raug txo, uas yuav cuam tshuam rau qhov ruaj ntseg, yog li peb yuav tsum tau sim kom tsis txhob muaj nws.

Yog tias tus hniav hniav tsawg dua 17, txhawm rau tiv thaiv kev txiav txim siab,Xuzhou Wanda Rinking Nplhaib Cov KabmobYuav txiav ib tug fillet los ntawm kev cuam tshuam ntawm cov iav hauv paus thaum machining lub iav, lossis nce kev hloov kho cov coefficient.

Yog koj muaj lus nug txogCov Kab Mob Slewing, thovTiv Tauj Peb.

Lub Sijhawm Post: Mar-14-2023