Muaj ob homLub Suab RearingKev puas tsuaj, ib qho yog kev puas tsuaj raceway, thiab lwm yam yog cov hniav tawg. Cov nyiaj sib koom ua ke ua kom muaj ntau dua 98%, yog li qhov zoo ntawm kev sib tw yog qhov tseem ceeb cuam tshuam rau lub neej ntawm lubLub Suab RearingCov. Ntawm lawv, Raceway hardness, hardened txheej qhov tob, kev sib tw xov hluav taws xob thiab hu rau kaum yog plaub qhov tseem ceeb tshaj plaws uas cuam tshuam zoo.

1. Raceway hardness

Lub quenching hardness ntawm lubLub Suab RearingRaceway muaj kev cuam tshuam ntau dua rau nws cov lus ntsuas zoo li qub. Yog tias Rated Static yog 1 ntawm 55HRC, txoj kev sib raug zoo ntawm kev ntaus nqi ntawm cov kabmob thiab lub hardness ntawm kev sib tw yog raws li hauv qab no:

| Raceway Hardness Hrc | 60 | 59 | 58 | 57 | 56 | 55 | 53 | 50 |

| Rated zoo li qub load | 1.53 | 1.39 | 1.29 | 1.16 | 1.05 | 1 | 0.82 | 0.58 |

TusCov Kab Mob Slewinglos ntawm xzwdCov Kab Mob SlewingTuam txhab Kev Ua Haujlwm Raceway Hardness yog 55HRC ~ 62hrc.

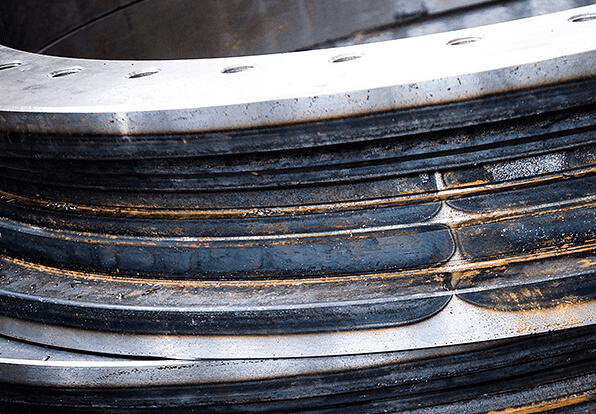

2.Qhov tob ntawm hardened txheej ntawm raceway

Qhov tsim nyog tob ntawm hardened txheej yog qhov lav uas covLub Suab RearingRaceway tsis yog spall. Thaum lubCov Kab Mob SlewingDais sab nraud thauj, cov pob txheem hlau thiab cov hlau pob thiab kev hloov pauv ntawm kev sib tw los ntawm taw tes sib cuag mus rau saum npoo sib tham, thiab cov chaw sib chwv yog ib qho chaw sib tiv tauj. Ntxiv nrog rau kev ntxhov siab compressive, cov kab ke sib tw kuj tseem muaj kev ntxhov siab ntau yam uas yog vim li cas lub cheeb tsamLub Suab Rearing, thiab tus nqi yam tsawg kawg nkaus lav tau muab rau hauv tus qauv. Qhov rated zoo li qub load c ntawm cov kabmob tau sib npaug rau qhov tob ntawm cov tawv tawv ntawm h0.908. Yog tias cov tawv tawv tawv uas yuav tsum muaj 4 hli tsuas yog quenched rau 2.5mm, cov kabmob qub qub load c yuav raug txo los ntawm 1 txog rau 0.65, qhov tshwm sim ntawm kev puas tsuaj rau lubCov Kab Mob SlewingVim kev ua kom muaj zog ua kom zoo nkauj yuav muaj ntau ntxiv.

Piv txwv li, tusCov Kab Mob SlewingRaceway Txheej Winf013.35.1250 raceway yog ≥ 3.5mm.

3.Txoj Kev Xaws Ntawm Kev Ncig Tebchaws

Lub Radius curiT yog hais txog kev nkhaus ntawm kev sib tw ntawm kev sib koom ua ke hauv ntu ntsug. Qhov ntsuas ntawm lub vojvoog ntawm lub vojvoog ntawm raceway rau lub vojvoog ntawm lub pob hlau kuj cuam tshuam rau qhov ntsuas ntsuas thiab qaug zog lub neej ntawm lubLub Suab RearingCov. Thaum t = 1.04, qhov ntsuas zoo li qub lub neej yog 1, thiab kev sib raug zoo ntawm cov rated zoo li qub static lub neej thiab qaug zog lub neej ntawm lubLub Suab Rearingthiab t yog li nram qab no.

| Txoj Kev Sib Tw Nkhaus | 1.04 | 1.06 | 1.08 | 1.10 |

| Rated zoo li qub load | 1 | 0.82 | 0.72 | 0.65 |

| Qaug zog lub neej | 1 | 0.59 | 0.43 | 0.33 |

Nws tuaj yeem pom los ntawm cov rooj saum toj no uas loj dua lub vojvoog piv, qis dua qhov ntsuas ntsuas thiab luv dua txoj kev pabcuam lub neej.

4.RACEWAY THAWJ LUB

Lub Chaw Sib Ntsib yog li lub kaum sab xis ntawm txoj kab txuas lub rooj sib chwv ntawm cov hlau pob thiab qhov chaw nruab nrab ntawm cov ntu (kab rov tav) ntawm covCov Kab Mob SlewingCov. Qhov rated zoo li qub load c ntawm lubLub Suab Rearingyog linearly proportional rau sinα, thiab thawj lub kaum sab xis yog feem ntau 45 °. Thaum lubCov Kab Mob SlewingMuaj qhov sib txawv, qhov tseeb ntawm lub kaum sab xis yog ntau dua li thawj lub kaum sab xis. Qhov loj dua qhov sib txawv, qhov loj dua qhov tseeb ntawm lub kaum sab xis. Nyob rau hauv qhov sib txawv ntawm cov qauv, nws yuav feem ntau nce los ntawm 2 10 ° ~ 10 ° ~ 5,5 ° ~ 5,5 °, uas yog qhov muaj peev xwm hloov rau cov kabmob muaj peev xwm. Tab sis yog tias lub kaum sab xis thawj lub thiab sib txawv yog loj, lub kaum ntse ntse tiag tiag yuav tshaj 60 °. Raws li cov ris tsho sib tw, cov kis yuav nce ntxiv thiab lub kaum sab xis tiag tiag tseem yuav nce ntxiv. Nyob rau lub sijhawm no, kev tiv toj ellipse yuav tshaj li ntawm ntug kev sib tw. , Lub zog tiag tiag ntawm kev sib koom ua ke yuav siab dua qhov theoretical suav kev ntxhov siab, uas yuav ua rau ntug ntawm kev sib tsoo thiab tusCov Kab Mob Slewingyuav swb.

Piv txwv li, tus thawj lub kaum ntawm lubCov Kab Mob Slewing013.40.1250 yog 45 °.

Ua tsaug rau kev rov xyuas cov kab lus no, yog tias koj muaj lus nug ntawmRearwing Nplhaib Cov Kabmob, tsuas yog xav tiv tauj peb!

Lub Sijhawm Post: Lub Yim Hli 20-2020